Kuasu Moldtec is a world-class ISO 9001:2015 certified manufacturer, who produces plastic injection molds and molded parts in the greater bay area of China. We are fully equipped to take your part from concept to real products.

Kuasu Moldtec is a world-class ISO 9001:2015 certified manufacturer, who produces plastic injection molds and molded parts in the greater bay area of China. We are fully equipped to take your part from concept to real products.

Kuasu Moldtec provides one-stop service and in mainly including of CAD /CAE Engineering, Mold Manufacturing, Checking Fixtures Building and Injection Molding Production. Please contact us for more capabilities may you need such as mold components, inserts, mold base, CNC milling parts, prototypes, 3D printed parts, etc.

Kuasu always takes care of your real needs, your satisfaction is our priority. We always work closely with you every step of the way to ensure your needs are met with excellence. Our excellent performance has been proved and praised by many of international well-known enterprises since years, you are risk-free to collaborate with us.

We have an international top - level team composed of members from different countries and regions. We fully understand your requirements, speak your language and respect your culture. Our mold experts possess diverse knowledge backgrounds and work with high professionalism to guarantee the production of the highest - quality molds that meet and even exceed industry standards.

We are proud of our meticulous attention to detail. We never simplify or omit procedures and steps, even when we are busy. We maintain the spirit of being scrupulous about every detail and striving for perfection. We strictly control every stage of production to ensure that all components are of superior quality.

We are specialized in providing services in the plastic injection mold industry, aiming to create products, parts, and components that are cost - saving, more durable, and more accurate. We understand your concerns, solve your problems, and take pride in your success. We will stand by you with 24/7/365 for just in case you need.

Kuasu Moldtec is a world-class mold manufacturer and we serve for very wide range of industries, which included of Automotive, Medical & Healthcare, Office & Home Appliances, Consumer & Electronics, Energy, Toys and Industrial, etc. Our skilled team work with the most advanced Technologies, Machines, Tools and software, to provide you a reliable single-source for all your needs with molds.

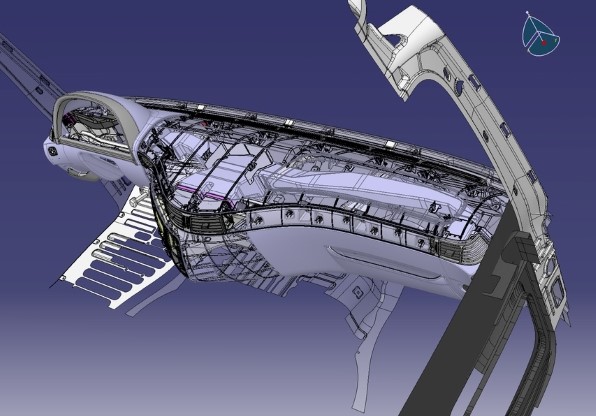

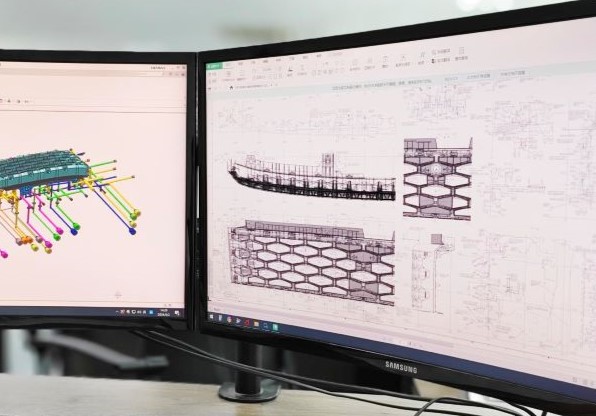

CAD / CAE Service

CAD Service:

• Creating of digital A-Surface and B-Surface with 3D solid model.

• Designing of Interior and Exterior parts and Adapting of existing design.

• Scanning and reverse engineering.

CAE Service:

• Part FEM Analysis, Structural Analysis, Thermal Analysis, Stress Analysis, Vibrational Analysis, etc.

• Part optimization and Weight reduction and validation using alternate materials.

Up Front Feasibility & Mold Designing

Our experienced designers are equipped with state-of-the-art software. They assess your part design and make modifications and recommendations based on key product requirements including product usage and function. We trust these Up front feasibility work and efficient solutions will meet and exceed your standards and expectations, such as:

• Design for manufacturability (DFM);

• Part Drafting for demolding and Structure optimization;

• MoldFlow analysis (Gate, Filling, Cooling, Clamping force, Air Trap, Cycle Time, Warping, etc.)

• Mold Design in 2D and 3D;

• Components GT&C drawings, Assembly geometry;

• CAM programing and electrodes design;

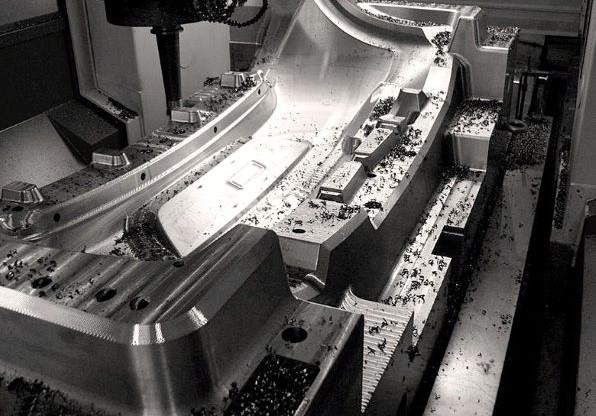

Component Fabricating & Mold Manufacturing

We have all kind of advanced machinery and equipment for the mold component fabricating. Everything is under one roof and nothing needs to be outsourced. Together with the unique exquisite skills what our design and production team has is the key to make us succeeded. The machines we have like:

• Manual Drillers and Gun-drillers; Mumerical control Tappers & Lathes; Automatic Grinders & Squarers;

• CNC Milling machines; EDM & Wire-EDM machines;

• Horizontal and Vertical Spotting machines;

• Laser welding & Cooling circulation tester;

• All kind of measurement machines and injection machines.

Mold Trial-outs & Sampling

Every single mold what Kuasu built has to be fully tested under the strict procedures. Our sampling engineer always follow and implement scientific trial principle, and never use one or certain method of mold verification. Through the superposition verification of multiple methods, we can completely close the possibilities of product defects caused by mold, these methods include but not limited as:

• Scientific Filling and Holding; Injection Speed and Curve Diagram; Filling Balance;

• Exploring Gate Freezing Point; Optimizing Cycle Time; Mold Function and Movement checking;

• Exploring the Optimal Process Parameter; Steel temperature checking and Hot spot finding;

• Water flow rate and Pressure loss checking; Synchronous work testing of robot gripper;

• 8-hours Continuous Mold Dry Running; CPK & PPK, Verification of Product Quality and Dimensions.

Steel & Part Measuring

Our quality control process begin since the raw material arriving into the factory. From steel blocks to component finished, from mold assembly to mold trial-out and until delivery, quality control runs through every step and department. Our inspection or measuring methods included but not limited as:

• Rockwell hardness (HRC) & Vickers hardness (HV) and Coating thickness test;

• Surface roughness check, Balance scale and all Regular measuring;

• Optical projector, Coordinate Measuring Machine (CMM) and Laser scanner;

• Water flowmeter, Thermometer & Colorimeter;

• FAI, Cpk, Ppk, SPC, MSA, FMEA, APQP, PPAP and GR&R.

Samples Delivering & Mold Transportation

Whatever for the delivery of samples, molded parts or the molds, we can always provide you a wide selection and solution in between the most economic, reliable and the fastest way. DHL, FedEx and UPS offers 24/7 service and committed lead time from booking to arriving within 72 hours, means we have the tool tested on Friday and you have the parts in hands on coming Monday. Air freight for a large quantity of sampled parts or under middle size of molds still is the most right choice, quick enough but reasonable transportation cost. Sea freight is the most economic way to have your molds delivered. Around 5,000USD cost we could get a twenty feet container reached at most of the ports in the world within 4 weeks. China-Europe Railway Express has provided a more reliable alternative to traditional shipping methods. The railway network has reached 217 cities in over 25 European countries.

Mold Life Warranty & After-sales Service

We are always responsible for the warranty issue even it is less likely. Please let us know in the first place, we will help you to judge and find solutions. Whatever for the warranty, or your engineering modification demand, it depends on what necessary that we can build a new replacement part and send over in an extremely quick way, or we can send our partners or specialist to you and have the issue fixed on-spot. Either we can take the tool back to our local owned satellite or cooperated tool shops. We can provide local service at:

Southeast Asia region, Singapore;

European Union area, Germany;

North American Free Trade Area (NAFTA), USA;

African continent Region, South African.

Plastic Injection Molded Parts

Custom Injection Molding division of Kuasu Moldtec, is a turnkey and full-service plastic injection molding shop that handles your manufacturing needs from design to fabricating molds. We offer you all of these services under one roof, we can begin immediate production of parts with your existing molds or we can help turn your concept into a finished product. The Injection machine size we have as:

80 Tons / 120 Tons / 160 Tons

200 Tons / 250 Tons / 300 Tons

350 Tons / 450 Tons / 650 Tons

1000 Tons