A die-casting mold is a tool for casting metal parts. It is a tool that completes the die-casting process on a dedicated die-casting die forging machine. The basic process of die casting is: the molten metal is first cast at low speed or high speed and filled into the cavity of the mold. The mold has a movable cavity surface, which is pressurized and forged as the molten metal cools. The alloys used in die castings are mainly non-ferrous alloys, with aluminum alloys being the most widely used.

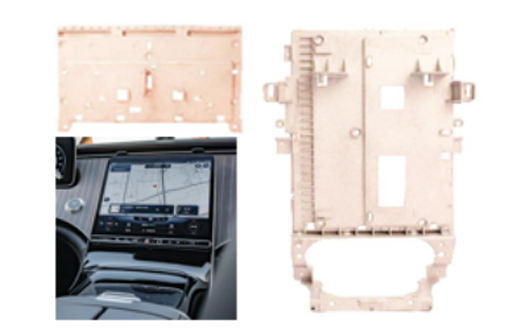

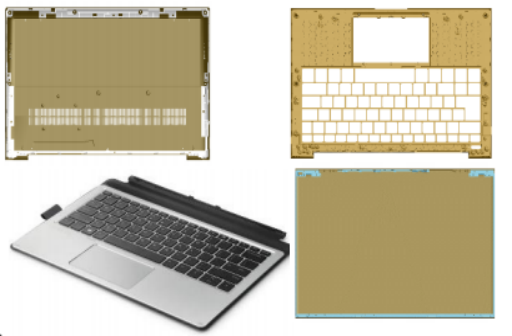

We KUASU have made many die-casting molds around automobile engines and die-casting molds for laptop casings for well-known brand customers.

Our Die Casting Molds are designed to meet the highest standards of quality and performance. Die casting is a process where molten metal is forced under high pressure into a mold cavity to create parts with excellent surface finish and high dimensional accuracy. This process is ideal for producing complex, high-strength components with tight tolerances and minimal post-production work.

Die casting involves injecting molten metal—typically aluminum, zinc, magnesium, or other non-ferrous metals—into a mold cavity at high pressure. The process is ideal for producing parts with consistent dimensions and complex geometries. Some of the key benefits of die casting include:

High-Volume Production: Die casting is perfect for large production runs, as it is a highly efficient and automated process that reduces unit costs over time.

Excellent Surface Finish: The process results in parts with a smooth, high-quality surface finish that requires little to no additional finishing, making it ideal for applications where aesthetics are important.

Tight Tolerances: Die casting can produce parts with extremely tight tolerances, making it an excellent choice for industries such as automotive and electronics, where precision is critical.

Strong and Lightweight Parts: Die cast parts are known for their excellent strength-to-weight ratio, which is why they are commonly used in the automotive and aerospace industries.

Die casting involves injecting molten metal—typically aluminum, zinc, magnesium, or other non-ferrous metals—into a mold cavity at high pressure. The process is ideal for producing parts with consistent dimensions and complex geometries. Some of the key benefits of die casting include:

High-Volume Production: Die casting is perfect for large production runs, as it is a highly efficient and automated process that reduces unit costs over time.

Excellent Surface Finish: The process results in parts with a smooth, high-quality surface finish that requires little to no additional finishing, making it ideal for applications where aesthetics are important.

Tight Tolerances: Die casting can produce parts with extremely tight tolerances, making it an excellent choice for industries such as automotive and electronics, where precision is critical.

Strong and Lightweight Parts: Die cast parts are known for their excellent strength-to-weight ratio, which is why they are commonly used in the automotive and aerospace industries.

There are numerous advantages to using die casting molds, especially when compared to other manufacturing methods:

High Precision: Die casting can achieve extremely tight tolerances, ensuring that every part produced meets exact specifications. This makes it ideal for industries like automotive, medical devices, and electronics that require parts with high accuracy.

Cost Efficiency in Mass Production: Once the mold is created, die casting allows for high-volume production with minimal additional costs. The process is highly automated, reducing labor costs and increasing overall production efficiency.

Complex Shapes and Details: Die casting can produce parts with intricate shapes and fine details, including internal cavities, thin walls, and complex features that would be difficult or impossible to achieve with other methods.

Fast Production Time: Die casting is one of the fastest manufacturing processes for producing metal parts, especially in high-volume runs. This allows businesses to meet tight deadlines while maintaining high product quality.

Durability and Strength: Parts produced through die casting are known for their exceptional mechanical properties, including high strength and resistance to wear and corrosion. These qualities make die-cast components ideal for heavy-duty applications.

At Kuasu Moldtec, we offer a comprehensive range of die casting mold services, including:

Custom Mold Design: Our experienced engineers work closely with you to create custom molds that meet your exact specifications, whether you need a prototype or high-volume production molds.

Prototyping and Testing: Before mass production, we can create prototype parts to test and validate the design. This helps to identify any potential issues early in the process, ensuring that the final product meets your expectations.

High-Volume Production: With our advanced die casting machines and automated production systems, we can efficiently produce large volumes of high-quality parts in a short amount of time.

Post-Casting Services: We offer a range of post-casting services, including machining, painting, surface finishing, and assembly to ensure that your parts are ready for immediate use.

Quality Assurance: Every die-cast part we produce undergoes stringent quality control checks to ensure it meets the highest standards of performance, durability, and appearance.

We understand that selecting the right die casting partner is critical to the success of your project. Some of the key concerns that our clients often face include:

Cost Control: Our efficient die casting process and expertise in material selection help minimize production costs while maintaining the highest quality standards.

Quality Consistency: We adhere to strict quality control protocols to ensure that every part produced is consistent and meets the required specifications.

Speed and Delivery: At Kuasu Moldtec, we understand the importance of meeting deadlines. Our fast production times and streamlined processes ensure that your products are delivered on schedule.

Complex Design Challenges: If your parts require complex geometries, thin walls, or intricate details, our experienced engineers and advanced technology allow us to meet these challenges with ease.

At Kuasu Moldtec, we are committed to providing you with top-quality Die Casting Molds and ensuring the success of your projects. Whether you need high-volume parts for automotive applications, consumer electronics, or medical devices, our team is here to support you every step of the way.

Contact us today to discuss your die casting needs and discover how we can help bring your ideas to life with precision and efficiency.

Read More

Die Casting: Zine、Aluminum & Magnesium

Throttle. Brake.

lamp

Car Center Controls

Automobile engine periphery

Laptop Accessories

Intake manifold