Kuasu Moldtec is a plastic injection molding manufacturer and supplier specializing in thermoplastic injection technology. Our expertise also extends to gas injection technology, high-gloss, and electronic molding. The injection-molded automotive interior and exterior parts we produce for the automotive industry are primarily made from the following materials: - Polystyrene (PS), - Polypropylene (PP), - ABS, - Polycarbonate (PC), - PC/ABS, - PC/PMMA.

Kuasu has a unique advantage in the field of automotive parts and accessories, especially interior and exterior parts. We are especially good at designing and manufacturing injection molds for medium-large and complex strutures. Serving the world's top 100 auto parts customers, we have experience in cooperation and know the product standars. It is not an exaggeration to say that we can make injection molds for any injection molded parts in car. At persent, we have provided more than 90%of the injection molds for a car . Bore, Lear, Yangfeng, Magna, Aisin Seiki, etc. are our cooperative customers. We have been awarded the Tier 1 and Tire 2 supplier code of many car companies.

For the dynamic automotive industry, we are a reliable partner in the production of various injection-molded interior components. In our ISO-certified factory, we undertake interior component projects for leading automotive manufacturers. We are experienced OEMs, Tier 1 automotive suppliers, and manufacturers of automotive interior and exterior parts. Our portfolio of interior injection-molded components includes plastic automotive parts such as: dashboard elements (e.g., glove boxes, door pillars), steering column trim, door handles, vents, center consoles, roof modules, and more.

Injection molding is an ideal technology for manufacturing a variety of exterior automotive parts. Our team of experienced injection molding professionals works closely with automotive OEMs and Tier 1 customers to assess and define all technical requirements, thereby optimizing the production of impeccable exterior automotive components. We are a plastic injection molding manufacturer for automotive exterior parts, such as: fenders (mudguards), wheel arches, grilles, sensor brackets, floor rails, trunk trim front and rear covers, bumpers, and exterior door trim, door panels. Our automotive injection-molded plastic parts are found in various vehicle models around the globe.

Injection molding is a manufacturing process that involves injecting molten material, typically plastic, into a mold cavity under high pressure. The material cools and solidifies, taking the shape of the mold. This process is highly suitable for producing high-precision parts with complex geometries, tight tolerances, and high repeatability, making it ideal for the automotive industry.

High Precision and Consistency: Injection molding delivers parts with tight tolerances and high repeatability, ensuring consistency across large production runs. This is crucial for the automotive industry, where precision is key to performance, safety, and fit.

Complex Geometries: Injection molding allows the production of highly complex parts with intricate designs and thin walls. This capability is especially valuable in automotive components that require specific forms, such as aerodynamic parts or detailed interior trims.

Durability and Strength: The materials used in automotive injection molding, such as PP, ABS, and PC, offer superior strength and impact resistance, making them suitable for high-performance automotive applications where durability is essential.

Cost Efficiency for Mass Production: Once the injection mold is created, the process allows for high-volume production at relatively low per-unit costs. This makes it a highly cost-effective solution for manufacturing large quantities of automotive parts.

Lightweight Components: Many of the materials used in automotive injection molding, such as PP and Nylon, offer lightweight properties that help improve fuel efficiency and reduce the overall weight of vehicles.

Enhanced Safety Features: The high precision of injection molding ensures that critical automotive components, such as bumpers and crash zones, are produced to meet safety standards, providing better protection for passengers in the event of an accident.

At Kuasu Moldtec, we offer a comprehensive range of services for automotive injection molded parts, including:

Custom Mold Design: Our team of engineers works closely with you to design custom molds that meet your exact specifications, ensuring that the final parts meet your quality, performance, and cost requirements.

Rapid Prototyping: We provide prototype injection molding services to help you validate the design and functionality of your parts before full-scale production. This allows you to test and refine your designs to ensure optimal performance.

High-Volume Production: With our advanced injection molding machines and automated processes, we can produce large volumes of automotive parts quickly and efficiently, ensuring consistent quality and fast delivery.

Post-Molding Services: We offer a range of secondary services such as painting, coating, assembly, and machining to ensure that your parts are fully functional and ready for integration into the final vehicle assembly.

Quality Assurance: Every part we produce undergoes rigorous quality control testing to ensure that it meets the highest standards of durability, precision, and performance. Our team is dedicated to delivering parts that exceed your expectations.

At Kuasu Moldtec, we are committed to providing automotive injection molded parts that meet the highest standards of performance, safety, and efficiency. Whether you need components for exterior, interior, or functional automotive parts, we have the capabilities and expertise to deliver the solutions you need.

Contact us today to learn more about how our injection molding services can help you achieve your automotive manufacturing goals.

Interior Trims

Door Panel

This automotive mould has below features:

1、The part is about 750X600mm size;

2、Large part and large tool; can be single cavity tool either 1+1 family tool as left and right. leather grain surface.

3、Many lifters and hot runner nozzles; and loudspeaker honeycomb cover.

Liftgate Panel

This automotive mould has below features:

1、The part is about 1100X550mm size;

2、Large part and large tool and leather grain surface.

3、Many lifters and ribs at back side.

Seat back cover

This automotive mould has below features:

1、The part is about 650X400mm size;

2、Reversed injection and leather grain surface.

3、TST water manifold system and Kistler pressure sensor, Laser harden parting lines.

A Pillar

This automotive mould has below features:

1、The part is about 750X120mm size;

2、1+1 cavity family mold with sequential controlled valve gates.

3、Laser grain surface and loudspeaker honeycomb cover.

Seat side cover

This automotive mould has below features:

1、The part is about 750X120mm size;

2、1+1 cavity family mold with sequential controlled valve gates.

3、Laser grain surface and loudspeaker honeycomb cover.

Garnish Panel

This automotive mould has below features:

1、The part is about 750X650mm size;

2、Large part and large tool; can be single cavity tool either Stack 1+1 family tool as left and right. leather grain surface.

3、Many lifters and hot runner nozzles and injected at the back side as reversed.

Center Console Cover

This automotive mould has below features:

1、The part is about 500X300mm size;

2、Single cavity tool with IMD (In-Mold decorating) technology with wood foil.

3、5 drops valve gates and injection from the back side.

Glove Box

This automotive mould has below features:

1、The part is about 400X300mm size;

2、There are glove box, cover and trigger parts in the assembly.

3、The box is very complicated part and tool structure with big sliders. leather grain surface on the cover and flocked inside of the box.

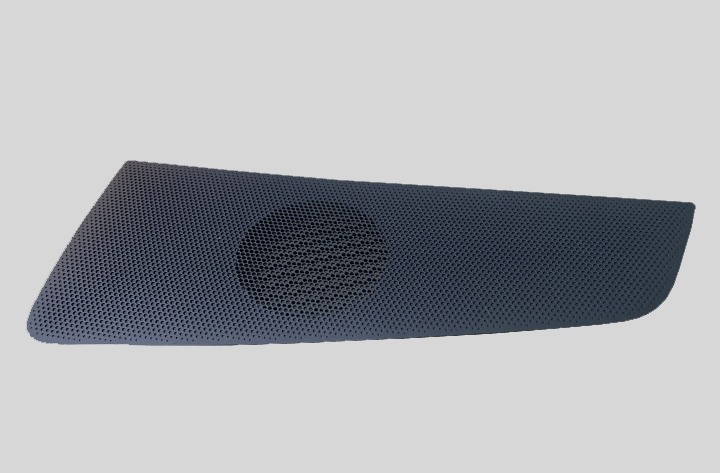

Speaker Cover

This automotive mould has below features:

1、The part is about 350X120mm size;

2、Honeycomb completed cover the cavity surface which is done by super EDM.

3、8 drops valve gates hot runner and injected at the back side as reversed.

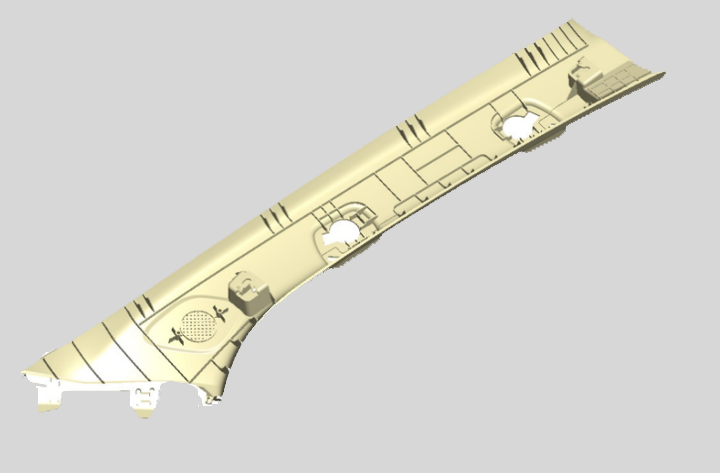

Door Frame Liftgate

This automotive mould has below features:

1、The part is about 1200X500mm size;

2、Gas-assisted; leather grain surface.

3、Very Complicated part and tool structure with big sliders.

Exterior Trims

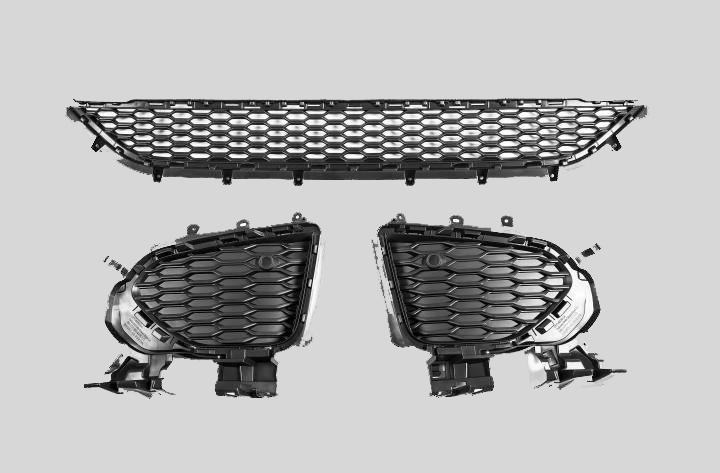

Grilles

This automotive lighting mould has below features:

1. Deep cavity mould.

2. Big drop of the parting ling surface.

3. Complicated part structure.

Non-visible structurals

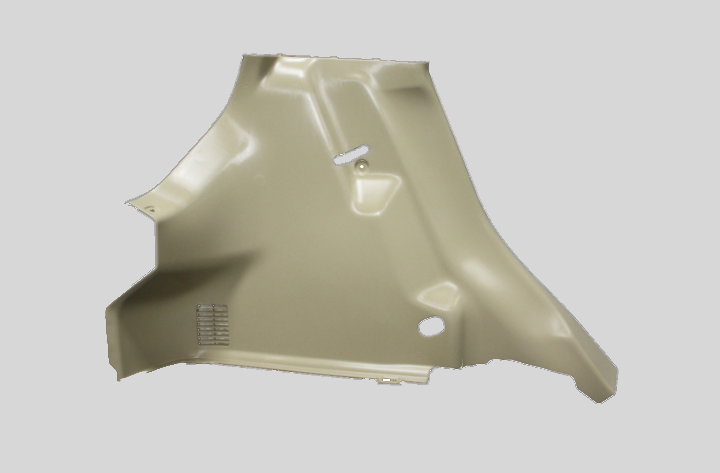

Door Carrier

This automotive lighting mould has below features:

1、The part is about 700X500mm size;

2、Long glass fiber mixed resin, which requested special technology in hot runner and tool building method to avoid the broken GF;

3、Very big warpage on part, needs special know-how to correct it.

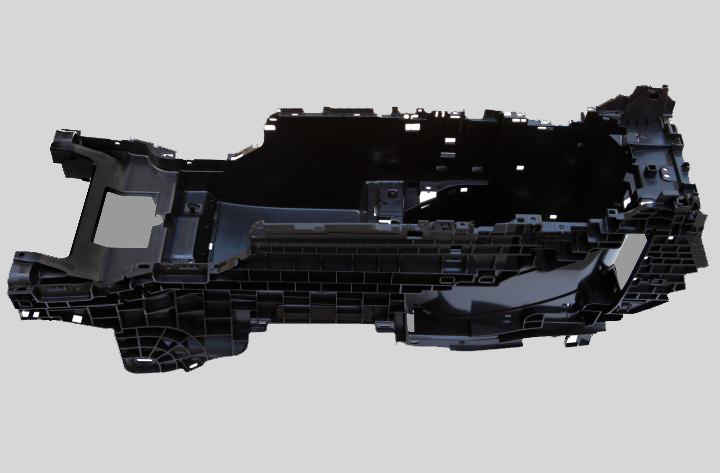

Front-End Module (FEM Carrier)

This automotive lighting mould has below features:

1、The part is about 1200X500mm size;

2、Long glass fiber mixed resin, which requested special technology in hot runner and tool building method to avoid the broken GF;

3、large size part and Tool, 1500T injection machine at least, with 3 RJG pressure sensors.

Intake manifold

This automotive lighting mould has below features:

1、The part is about 400X300mm size;

2、Very Complicated part and tool structure.

3、Tight profile tolerance request for welding Upper, Middle and Lower together.

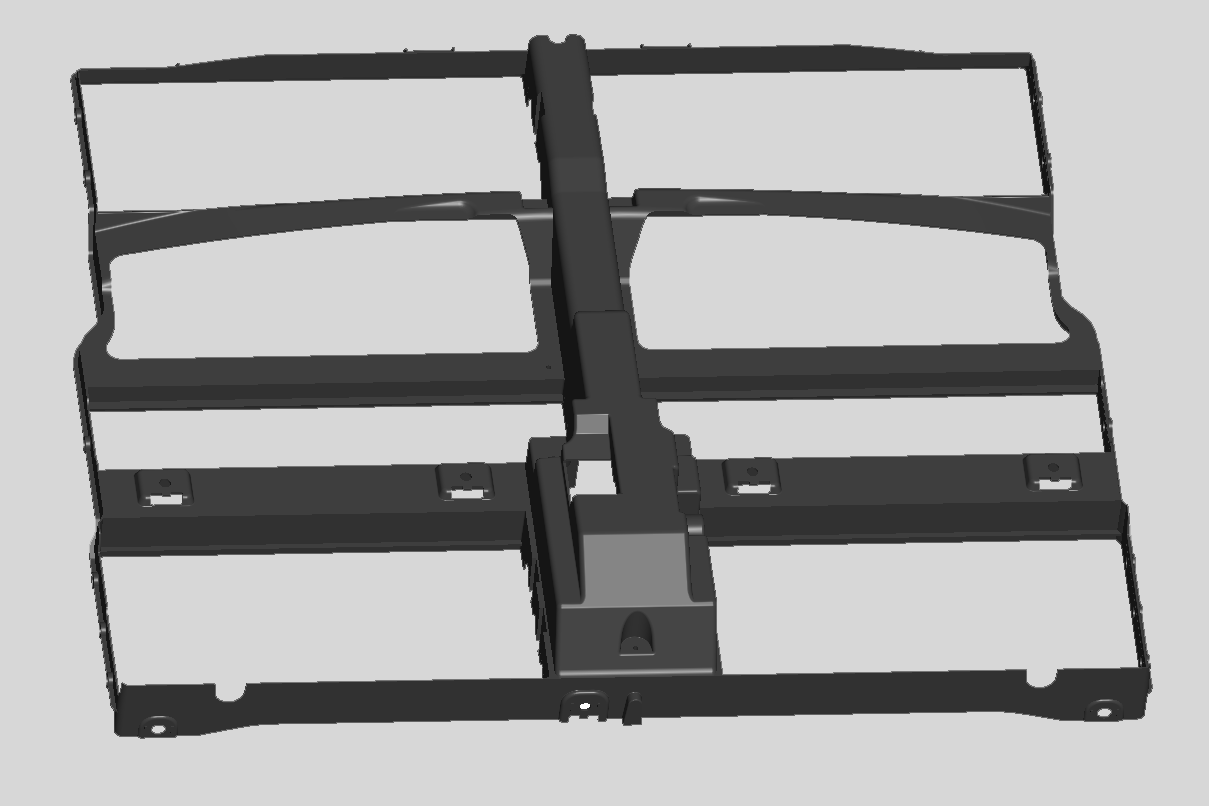

Sun roof assembly

This automotive lighting mould has below features:

1、It is two parts in the assembly, front and rear frame. The part is about 900X350mm size for each;

2、Very Complicated part and a lot of shutoff details.

3、Very big warpage on part, needs special know-how to correct it.

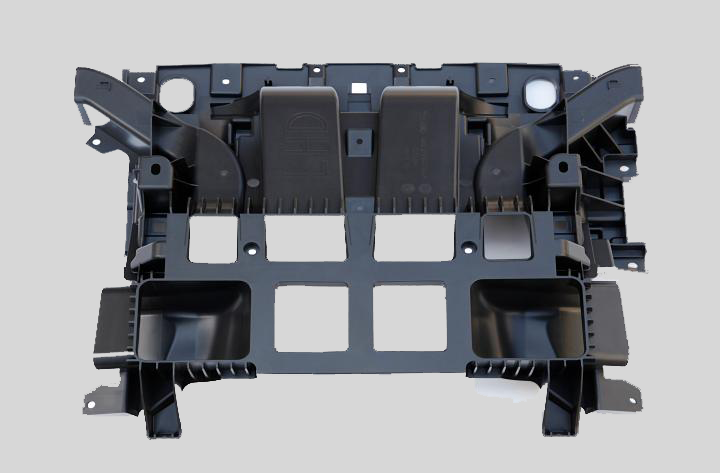

Center Console Carrier

This automotive lighting mould has below features:

1、The part is about 700X350mm size;

2、Very complicated part and a lot of ribs working on tool.

3、Large tool, 4 sides big sliders with Ejector Pin system.

Air Gate

This automotive lighting mould has below features:

1、The part is about 750X600mm size;

2、6 drops valve needle gates hot runner.

3、Very big warpage on part, needs special know-how to correct it.

AVAC Cover

This automotive lighting mould has below features:

1、The part is about 550X300mm size;

2、Very complicated part and a lot of ribs working on tool. Staubli water manifold system.

3、Large tool and mostly 1+1 cavity tool as Upper and Lower together.

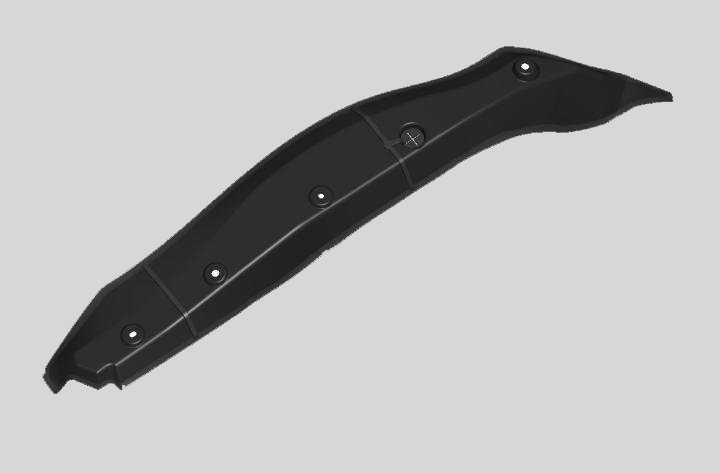

Cover Wing

This automotive lighting mould has below features:

1、The part is about 750X150mm size;

2、Resin is PP-EPDM+TPR, L+R in total 4 cavity..

3、Large rotating 2K mold, laser hardened parting lines.

Engine Cover

This automotive lighting mould has below features:

1、The part is about 650X550mm size;

2、6 drops valve needle gates hot runner.

3、Large tool on 1300T injection molding machine.

Active Grille System (AGS)

This automotive lighting mould has below features:

1、The frame part is about 680X400mm size;

2、there is 1 frame and 10 laminae in the assembly.

3、Large Core Back System 2K tool for the frame, and rotating 2K for the laminae.