Kuasu Moldtec is a world-class ISO 9001:2015 certified manufacturer, who produces plastic injection molds and molded parts in the greater bay area of China. We are fully equipped to take your part from concept to real products.

Kuasu Moldtec is a world-class ISO 9001:2015 certified manufacturer, who produces plastic injection molds and molded parts in the greater bay area of China. We are fully equipped to take your part from concept to real products.

Kuasu Moldtec provides one-stop service and mainly including of CAD /CAE Engineering, Mold Manufacturing, Checking Fixtures Building and Injection Molding Production. Please contact us for more capabilities you need such as mold components, inserts, mold base, CNC milling parts, prototypes, 3D printed parts, etc.

“At Kuasu, we prioritize your real needs and satisfaction above all else. We work closely with you at every step of the process to ensure that your needs are met with the utmost excellence. Our exceptional performance has been recognized and praised by numerous internationally renowned enterprises for many years, making us a reliable and risk-free partner for collaboration.”

Our team is composed of top-tier professionals from diverse international backgrounds. We have a deep understanding of your needs, communicate fluently in your language, and respect your cultural nuances. Our mold experts, with their extensive knowledge and high level of professionalism, ensure the production of molds that not only meet but also surpass industry standards

We take pride in our meticulous attention to detail. Regardless of our workload, we never compromise on procedures or overlook steps. We uphold a rigorous commitment to precision and perfection, meticulously examining every detail. Our stringent quality control processes span every phase of production, ensuring that each component meets the highest standards of excellence.

We specialize in offering services within the plastic injection molding industry, dedicated to crafting products, parts, and components that are cost-effective, durable, and precise. We are attentive to your concerns, proactive in solving your issues, and share in your success. Our commitment to you is unwavering, with round-the-clock support available 24/7/365, ensuring we are here for you whenever you need assistance.

Kuasu Moldtec is a world-class mold manufacturer and we serve for very wide range of industries, which included of Automotive, Medical & Healthcare, Office & Home Appliances, Consumer & Electronics, Energy, Toys and Industrial, etc. Our skilled team work with the most advanced Technologies, Machines, Tools and software, to provide you a reliable single-source for all your needs with molds.

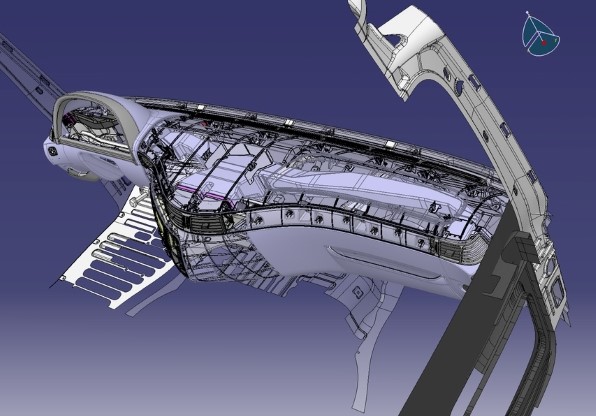

CAD / CAE Service

Comprehensive CAD & CAE Solutions for Automotive Plastics

Kuasu is your single-source partner for all automotive plastic part design needs. We support Tier-1 and Tier-2 suppliers with end-to-end computer-aided design (CAD) and computer-aided engineering (CAE) services, ensuring precision, performance, and manufacturability.

CAD Services:

3D Modeling & Surfacing: High-quality A-Surface (Class-A) and B-Surface development with solid modeling.

Interior/Exterior Part Design: Custom solutions from concept to production, including design adaptation.

Reverse Engineering: 3D scanning and digital reconstruction for legacy parts or design improvements.

CAE Services:

Advanced Simulation: Finite Element Analysis (FEA), structural, thermal, stress, and vibrational analysis.

Optimization & Validation: Weight reduction, material substitution studies, and performance validation.

Streamline your workflow with Kuasu’s integrated expertise—where innovative design meets engineering excellence.

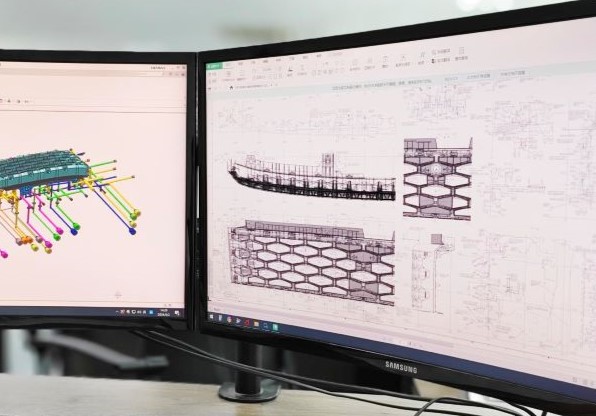

Up Front Feasibility & Mold Designing

Upfront Feasibility & Mold Design Excellence

Our expert design team leverages cutting-edge software to evaluate your part design, providing data-driven modifications and recommendations tailored to your product’s function, performance, and manufacturability needs. Through rigorous upfront feasibility analysis, we deliver solutions that not only meet but exceed your quality and efficiency expectations—reducing costs and accelerating time-to-market.

Key Services Include:

✔ Design for Manufacturability (DFM) – Optimize part geometry for seamless production.

✔ Drafting & Structural Optimization – Enhance demolding efficiency and part integrity.

✔ Comprehensive MoldFlow Analysis – Simulate gate placement, filling patterns, cooling, clamping force, air traps, cycle time, and warpage to prevent defects.

✔ Precision Mold Design – 2D & 3D mold development with detailed component drawings (GT&C) and assembly geometry.

✔ CAM Programming & Electrode Design – High-accuracy tooling for complex molds.

From concept to production-ready tooling, we bridge innovation with precision engineering.

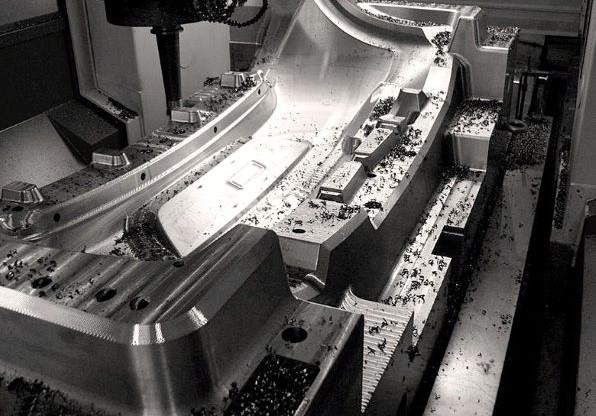

Component Fabricating & Mold Manufacturing

Precision Mold Component Fabrication & Manufacturing

At Kuasu, our fully integrated manufacturing facility houses state-of-the-art machinery operated by skilled technicians - eliminating the need for outsourcing and ensuring complete quality control. Our unique combination of advanced equipment and engineering expertise delivers superior mold manufacturing solutions.

Our Comprehensive Manufacturing Capabilities Include:

CNC Machining Centers: High-precision milling for complex geometries

EDM Solutions: Conventional EDM and Wire-EDM for intricate details

Specialized Drilling Equipment: Manual drillers, gun-drillers, and CNC tappers

Precision Grinding & Finishing: Automatic grinders and squares

Complete Inspection Suite: Advanced measurement systems for quality assurance

Support Equipment: Laser welding, cooling circulation testers, and injection machines

Mold Trial-outs & Sampling

Precision Mold Testing & Sampling Process

At Kuasu, every mold undergoes rigorous testing under strict quality protocols. Our sampling engineers follow scientific trial methodologies—never relying on a single verification approach. Through multi-layered validation, we eliminate potential defects and ensure mold reliability before production begins.

Comprehensive Verification Methods Include:

✔ Process Optimization: Scientific filling/holding patterns, injection speed profiling, and cycle time analysis

✔ Gate & Cooling Validation: Gate freezing point studies, water flow/pressure loss measurement, and hot spot detection

✔ Functional Testing: Mold movement verification and robotic gripper synchronization

✔ Durability Testing: 8-hour continuous dry runs and steel temperature monitoring

✔ Statistical Quality Control: CPK/PPK analysis with full dimensional inspection

We don’t just test molds—we engineer out risks.

Steel & Part Measuring

“End-to-End Quality Assurance: From Raw Material to Final Delivery

At Kuasu, our quality control process begins the moment raw materials enter our facility and continues through every production stage until final delivery. We maintain rigorous inspection protocols across all departments to ensure consistent excellence in both components and finished molds.

Comprehensive Quality Control Measures Include:

✔ Material Testing:

Hardness verification (Rockwell HRC & Vickers HV)

Coating thickness analysis

Surface roughness measurement

✔ Precision Metrology:

3D measurement with optical projectors and CMM

Laser scanning for complex geometries

Traditional dimensional inspection tools

✔ Process Validation:

Cooling system verification (water flow rate, temperature)

Color consistency checks

Full Advanced Product Quality Planning (APQP) implementation

✔ Statistical Quality Systems:

First Article Inspection (FAI)

Process capability studies (Cpk/Ppk)

Statistical Process Control (SPC)

Measurement System Analysis (MSA)

Failure Mode Effects Analysis (FMEA)

Production Part Approval Process (PPAP)

Gauge Repeatability & Reproducibility (GR&R)

Our multilayered approach to quality ensures every component meets the most demanding specifications before advancing to the next production phase.

Samples Delivering & Mold Transportation

Efficient Sample Delivery & Mold Transportation Solutions

At Kuasu, we offer flexible and reliable shipping options for samples, molded parts, and molds—tailored to your budget, timeline, and requirements. Whether you need speed, cost efficiency, or a balance of both, we provide optimized logistics solutions for every scenario.

Fast & Reliable Options:

✔ Express Courier (DHL/FedEx/UPS):

Ideal for urgent sample deliveries

Door-to-door service with committed lead times (as fast as 72 hours)

Example: Mold tested on Friday → parts in hand by Monday

✔ Air Freight:

Best for medium-sized molds or larger quantities of sample parts

Faster than sea freight with reasonable costs

Cost-Effective Solutions:

✔ Sea Freight:

Most economical for full mold shipments

20' container (approx. $5,000 USD) delivers to major global ports in ≤4 weeks

✔ China-Europe Railway:

Faster than sea freight, more affordable than air

Connects to 217 cities across 25+ European countries

Stable schedules and reduced transit times

We ensure secure packaging, real-time tracking, and smooth customs clearance—so your parts and molds arrive safely and on time.

Mold Life Warranty & After-sales Service

Global Warranty & Engineering Support

At Kuasu, we stand firmly behind our products. While quality issues are rare, we’re committed to resolving any concerns quickly—whether through remote technical guidance, rapid part replacement, or on-site service.

Our Response Solutions Include:

✔ Expedited Replacement Parts – New components shipped immediately when required

✔ On-Site Technical Support – Deployment of our specialists or trusted partners for local repairs

✔ Return-to-Facility Service – Option to service tools at our owned or partnered workshops

Global Service Coverage:

• Southeast Asia: Singapore (hub)

• Europe: Germany (EU base)

• North America: USA (NAFTA region)

• Africa: South Africa (continental support)

• Latin America (Mexico + Brazil)

Simply notify us of any issue—we’ll promptly evaluate and implement the most efficient solution with minimal disruption to your operations.

Plastic Injection Molded Parts

Plastic Injection Molding Services

As the custom injection molding division of Kuasu Moldtec, we provide complete turnkey manufacturing solutions - from initial design to final production. Our full-service capabilities allow us to:

Transform your concepts into finished products

Manufacture parts using your existing molds

Deliver comprehensive molding solutions entirely in-house

Our Injection Molding Capabilities:

• Machine sizes ranging from 80 to 1000 tons

• Complete production capacity under one roof

• Seamless integration with our mold fabrication expertise

With presses from 80T to 1000T, we're equipped to handle projects of any scale while maintaining consistent quality and precision.